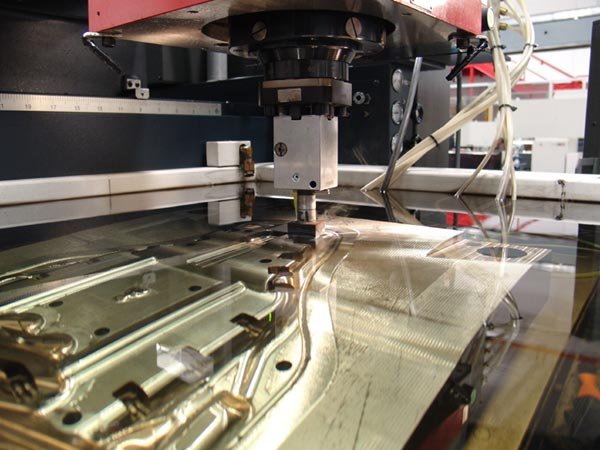

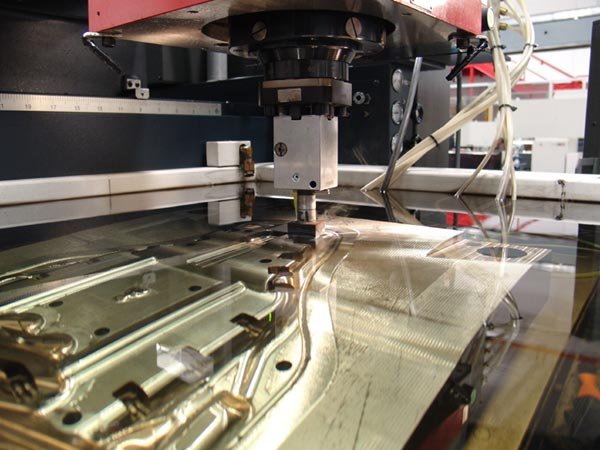

The electrical discharge vaporizes a small amount of material from the workpiece, and the process is repeated thousands of times per second. The sparks are precisely controlled, and the material removal rate can be adjusted to produce parts with high accuracy and surface finishes.

One of the advantages of EDM is its ability to machine hard materials that are difficult to cut with traditional #machining methods. Materials such as hardened steel, titanium, and carbide can be machined with EDM, producing parts with high precision and accuracy. EDM is also capable of producing parts with very fine surface finishes, which is important in applications such as #injectionmolding and #diecasting.

EDM is widely used in various industries, including #aerospace, #automotive, #medical, and #electronics. It is commonly used to produce parts with complex geometries, such as turbine blades, #gears, and molds. It is also used to produce small, intricate parts, such as microelectronic #components and medical #implants.

In conclusion, electrical discharge machining is a precise and versatile machining process that is widely used in various industries. It is capable of producing parts with high #accuracy , complex geometries, and fine surface finishes. With the ability to machine hard materials and produce small, intricate parts, EDM is a critical process for many applications.

Contact us today to get your #quote: cemil@partsclipper.com

#ElectricalDischargeMachining #EDM #PrecisionMachining #Manufacturing #Aerospace #Automotive #Medical #Electronics #MachiningTechnology #GraphiteElectrodes #CopperElectrodes